Werner Rädlinger Gruppe

Karriere

View product

Operating weight

11 - 50 t

Application

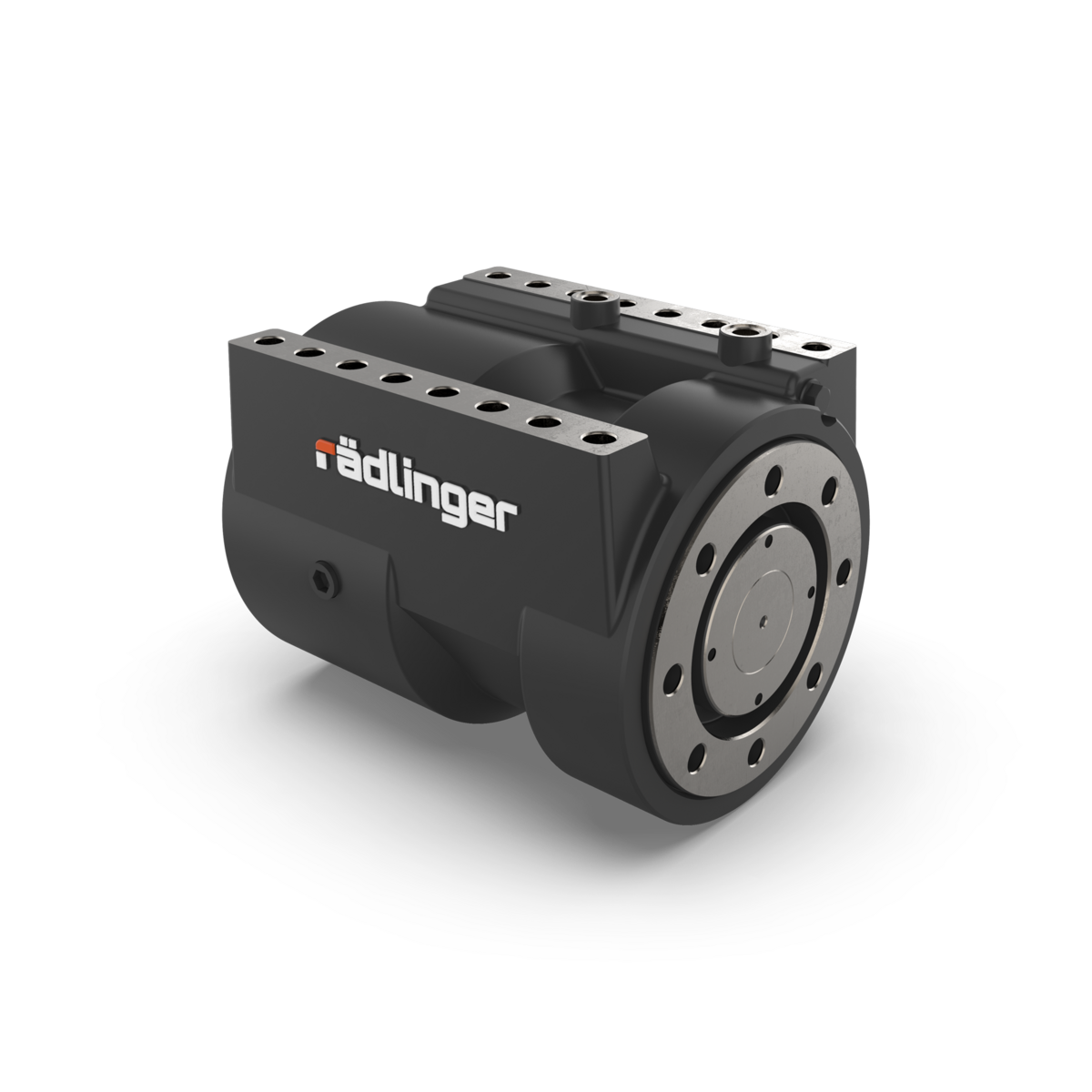

With the Rädlinger Tilt Motor, attachments can be tilted by 2 × 45°. Depending on size, a combination with either buckets or quick couplers is possible. This increases the performance of excavators as well as the efficiency of the attachments.

Features

- Tilt movement 2 × 45°

- Overload protection through double pressure relief valve

- Screwed and therefore exchangeable suspension

- Protected hydraulic connections

- Maintenance-free and wear resistant

- High holding and turning torques

- Combinations with other attachments possible

Extra equipment

- Special seal to protect the standard seal of the motor for use underwater or in fine sandy soils on request

Variants

| Dimensions (w x h x l) | 260 x 266 x 350 mm |

|---|---|

| Weight | 128 kg |

| Tilt angle (mechanically limited) | 90° |

| Torque | 8,500 Nm at 150 bar |

| Retention torque | 16.000 Nm |

| Oil requirement | 13,9 ccm/1° |

| Operating pressure | 150 bar |

| Maximum operating pressure (pressure relief valve) | 180 bar |

| Dimensions (w x h x l) | 310 x 363 x 368 mm |

|---|---|

| Weight | 185 kg |

| Tilt angle (mechanically limited) | 90° |

| Torque | 16,000 Nm at 150 bar |

| Retention torque | 30.000 Nm |

| Oil requirement | 24,8 ccm/1° |

| Operating pressure | 150 bar |

| Maximum operating pressure (pressure relief valve) | 180 bar |

| Dimensions (w x h x l) | 346 x 363 x 368 mm |

|---|---|

| Weight | 193 kg |

| Tilt angle (mechanically limited) | 90° |

| Torque | 16,000 Nm at 150 bar |

| Retention torque | 30.000 Nm |

| Oil requirement | 24,8 ccm/1° |

| Operating pressure | 150 bar |

| Maximum operating pressure (pressure relief valve) | 180 bar |

| Dimensions (w x h x l) | 362 x 371 x 420 mm |

|---|---|

| Weight | 237 kg |

| Tilt angle (mechanically limited) | 90° |

| Torque | 19,500 Nm at 150 bar |

| Retention torque | 38.000 Nm |

| Oil requirement | 29,1 ccm/1° |

| Operating pressure | 150 bar |

| Maximum operating pressure (pressure relief valve) | 180 bar |

| Dimensions (w x h x l) | 365 x 408 x 471 mm |

|---|---|

| Weight | 326 kg |

| Tilt angle (mechanically limited) | 90° |

| Torque | 23,000 Nm at 150 bar |

| Retention torque | 43.000 Nm |

| Oil requirement | 37,7 ccm/1° |

| Operating pressure | 150 bar |

| Maximum operating pressure (pressure relief valve) | 180 bar |

| Dimensions (w x h x l) | 405 x 448 x 540 mm |

|---|---|

| Weight | 460 kg |

| Tilt angle (mechanically limited) | 90° |

| Torque | 33,000 Nm at 150 bar |

| Retention torque | 62.000 Nm |

| Oil requirement | 55,1 ccm/1° |

| Operating pressure | 150 bar |

| Maximum operating pressure (pressure relief valve) | 180 bar |

| Dimensions (w x h x l) | 455 x 458 x 635 mm |

|---|---|

| Weight | 690 kg |

| Tilt angle (mechanically limited) | 90° |

| Torque | 47,000 Nm at 150 bar |

| Retention torque | 90.000 Nm |

| Oil requirement | 83,2 ccm/1° |

| Operating pressure | 150 bar |

| Maximum operating pressure (pressure relief valve) | 180 bar |